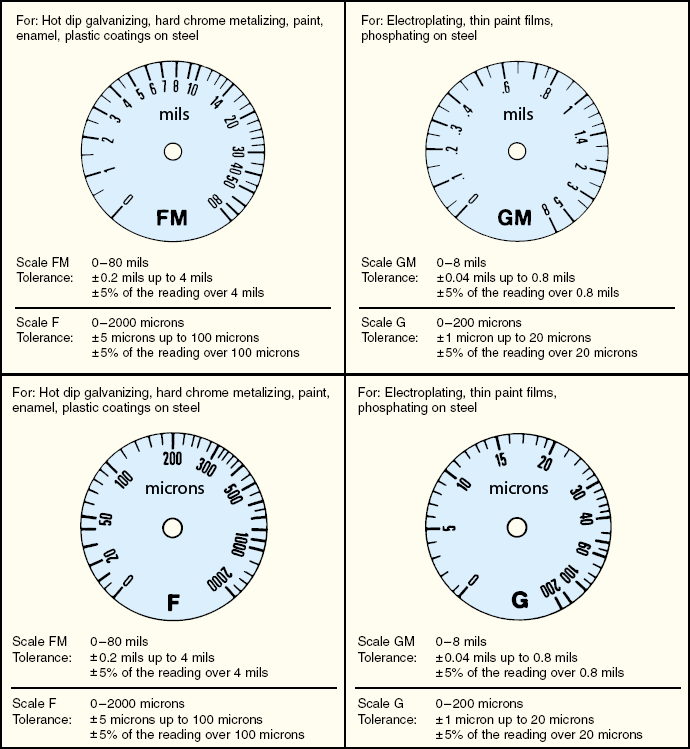

4 Ranges

Positest® GM: 0-8 mils

Positest® FM: 0-80 mils

Positest® FM: 0-80 mils

Positest® G: 0-200 microns

Positest® F: 0-2000 microns

Positest® F: 0-2000 microns

The Positest® coating thickness gauge is designed for the non-destructive measurement of nonmagnetic coatings such as (paint, enamel, plastic, galvanizing, metalizing, plating, etc.) on STEEL. Easily measures small parts of almost any shape. Stable design with additional tail-end support. No annoying rocking during measurement.

- Permanently calibrated

- “V” grooves in probe housing and Gage base allow correct positioning on cylindrical objects

- Highly wear resistant Carbide Probe for longest life and continuous accuracy

- Can be used underwater

- Extra rugged housing, not affected by mechanical shock, water, acid or solvents

- GO/NO-GO button can be pre-set for rapid measurement

- Explosion Proof – Refinery safe

- Made in the USA

- Supplied with Traceable Calibration Certificate

| Accuracy | GM: ±0.04 mils up to 0.8 mils ±5% of the reading over 0.8 mils FM: ±0.2 mils up to 4 mils ±5% of the reading over 4 mils G: ±1 microns up to 20 microns ±5% of the reading over 20 microns F: ±5 microns up to 100 microns |

| Dimensions | 8.5"L x 2"H x 1"W |

| Warranty | 1 year |

| Material Temperature | +32° to +120° F (0 to +50° C) |

| Weight | 6.1 oz |

Is the PosiTest® calibrated at the factory?

The PosiTest® arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements. The PosiTest® features a rare-earth permanent magnet that prevents any kind of drift over time. A PosiTest® gage that sits unused on a shelf for several years will not drift or lose its calibration.

Is the PosiTest® intrinsically safe?

“Intrinsically Safe” (I.S.) is commonly used to describe electronic products destined for a hazardous (explosive) operating environment. Owing to the mechanical (non-electronic) design of the PosiTest, it does not require certification as an “intrinsically safe” device.

Why should I purchase the PosiTest® over the PosiPen?

Compared with the PosiPen, the PosiTest® provides superior accuracy and improved ease-of-use by using a large dial to increase spring pressure, and by holding the displayed gage reading after being removed from the coated part. The PosiPen is ideal for small, hot or hard-to-reach surfaces.

Is the PosiTest® affected by the roughness of the steel substrate below the coating?

All coating thickness gages are influenced to some degree by substrate roughness. It is generally accepted that coating thickness should be measured from the highest ‘peaks’ in the rough surface thus ensuring they are covered by the protective coating. However, coating thickness gages will instead measure the coating thickness from the effective magnetic surface, which is located somewhere between the highest peaks and deepest valleys of the profile.

To compensate for the influence of substrate conditions (including roughness), measure the uncoated substrate/part at a number of spots to obtain a representative average value. This average value is called the “base metal reading” or “BMR”. Subtract the BMR from subsequent coating thickness measurements to obtain the thickness of the coating over the ‘peaks’ of the rough surface.

Can the PosiTest® measure nickel on steel?

Yes, but it depends upon the particular type of nickel coating that has been applied to the steel.

When nickel plating is deposited by a process of electrolysis (employing an electric current in the nickel bath), the resultant coating – commonly called “e-nickel” – is always conductive and magnetic to some degree and cannot be accurately measured by our gages when applied to ferrous or non-ferrous metals.

Electroless nickel coatings are deposited by an autocatalytic process which does not involve the addition of an electric current. If the nickel bath in this process contains a minimum concentration of ~8% phosphorus, the resulting nickel plating is effectively non-magnetic and its thickness can be accurately measured on ferrous steel with a magnetic principle coating thickness gage such as the PosiTest.

Does the PosiTest® measure on hot surfaces?

The operating temperature range of the PosiTest depends on the use case. The first case is where the measurement surface and the gage are both at the same temperature; in this case the operating range would be -10°C to 60°C (14°F to 140°F). The other case is where the PosiTest is at a “normal” room temperature but the measurement sample may be at a different temperature. In this case the PosiTest can measure on surfaces with temperatures ranging from -50°C to 100°C (-58°F to 212°F), so long as the instrument itself is kept within its operating range.

Can the PosiTest® be used underwater?

Yes. The PosiTest features corrosion-resistant brass construction and can be immersed in fresh or saltwater. When used in saltwater, it is recommended to rinse with freshwater after use.

Can the PosiTest® be adjusted?

While the PosiTest can be adjusted, this is not recommended for most applications. The permanent rare-earth magnet eliminates the need for adjustment, unlike other mechanical instruments. If a PosiTest is not functioning properly in accordance with NIST / PTB calibration standards we recommend the Gage be returned to us for a no-cost evaluation. Opening the PosiTest for purposes of cleaning, re-balancing and recalibration is not recommended.

Does the PosiTest® measure on non-ferrous metals, like aluminum?

No. As a magnetic principle instrument, the PosiTest will measure the thickness of non-magnetic coatings applied to ferrous metals. Our popular PosiTest DFT Combo and powerful PosiTector 6000 N gage models are ideal for measuring the thickness of paint, anodize and other non-conductive coatings applied to non-ferrous metals.

Is the PosiTest® ‘automatic’?

The PosiTest® is a simple, manually-operated coating thickness gage. The GO/NO-GO button can be preset for taking rapid, accurate measurements.

The PosiTest® arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements. The PosiTest® features a rare-earth permanent magnet that prevents any kind of drift over time. A PosiTest® gage that sits unused on a shelf for several years will not drift or lose its calibration.

Is the PosiTest® intrinsically safe?

“Intrinsically Safe” (I.S.) is commonly used to describe electronic products destined for a hazardous (explosive) operating environment. Owing to the mechanical (non-electronic) design of the PosiTest, it does not require certification as an “intrinsically safe” device.

Why should I purchase the PosiTest® over the PosiPen?

Compared with the PosiPen, the PosiTest® provides superior accuracy and improved ease-of-use by using a large dial to increase spring pressure, and by holding the displayed gage reading after being removed from the coated part. The PosiPen is ideal for small, hot or hard-to-reach surfaces.

Is the PosiTest® affected by the roughness of the steel substrate below the coating?

All coating thickness gages are influenced to some degree by substrate roughness. It is generally accepted that coating thickness should be measured from the highest ‘peaks’ in the rough surface thus ensuring they are covered by the protective coating. However, coating thickness gages will instead measure the coating thickness from the effective magnetic surface, which is located somewhere between the highest peaks and deepest valleys of the profile.

To compensate for the influence of substrate conditions (including roughness), measure the uncoated substrate/part at a number of spots to obtain a representative average value. This average value is called the “base metal reading” or “BMR”. Subtract the BMR from subsequent coating thickness measurements to obtain the thickness of the coating over the ‘peaks’ of the rough surface.

Can the PosiTest® measure nickel on steel?

Yes, but it depends upon the particular type of nickel coating that has been applied to the steel.

When nickel plating is deposited by a process of electrolysis (employing an electric current in the nickel bath), the resultant coating – commonly called “e-nickel” – is always conductive and magnetic to some degree and cannot be accurately measured by our gages when applied to ferrous or non-ferrous metals.

Electroless nickel coatings are deposited by an autocatalytic process which does not involve the addition of an electric current. If the nickel bath in this process contains a minimum concentration of ~8% phosphorus, the resulting nickel plating is effectively non-magnetic and its thickness can be accurately measured on ferrous steel with a magnetic principle coating thickness gage such as the PosiTest.

Does the PosiTest® measure on hot surfaces?

The operating temperature range of the PosiTest depends on the use case. The first case is where the measurement surface and the gage are both at the same temperature; in this case the operating range would be -10°C to 60°C (14°F to 140°F). The other case is where the PosiTest is at a “normal” room temperature but the measurement sample may be at a different temperature. In this case the PosiTest can measure on surfaces with temperatures ranging from -50°C to 100°C (-58°F to 212°F), so long as the instrument itself is kept within its operating range.

Can the PosiTest® be used underwater?

Yes. The PosiTest features corrosion-resistant brass construction and can be immersed in fresh or saltwater. When used in saltwater, it is recommended to rinse with freshwater after use.

Can the PosiTest® be adjusted?

While the PosiTest can be adjusted, this is not recommended for most applications. The permanent rare-earth magnet eliminates the need for adjustment, unlike other mechanical instruments. If a PosiTest is not functioning properly in accordance with NIST / PTB calibration standards we recommend the Gage be returned to us for a no-cost evaluation. Opening the PosiTest for purposes of cleaning, re-balancing and recalibration is not recommended.

Does the PosiTest® measure on non-ferrous metals, like aluminum?

No. As a magnetic principle instrument, the PosiTest will measure the thickness of non-magnetic coatings applied to ferrous metals. Our popular PosiTest DFT Combo and powerful PosiTector 6000 N gage models are ideal for measuring the thickness of paint, anodize and other non-conductive coatings applied to non-ferrous metals.

Is the PosiTest® ‘automatic’?

The PosiTest® is a simple, manually-operated coating thickness gage. The GO/NO-GO button can be preset for taking rapid, accurate measurements.

| Item | Description | Price | ||

|---|---|---|---|---|

PT-F | Positest® F Coating Gauge, 0-2000 microns scale | $350.00 |

In stock

1 Week Lead Time (Estimated)

2-3 Week Lead Time (Estimated)

Lead Time Varies, Please contact us for availability.

Unavailable